Categorie

Fine Pitch PCB Assembly

Fine Pitch PCB Assembly

What is Fine Pitch PCB Assembly?

Fine pitch PCB assembly means assembling the PCBs where the center-to-center distance between adjacent SMD pads and solder balls (BGA pins, IC pins, connector pins...) is extremely small. In other words, the components are close together on a PCB Board, and the high-speed and functional mounting machines for SMT assembly should have fine-pitch capabilities and accuracy.

With most electronic equipment trending towards compact designs, printed circuit boards inside them must support a substantial number of components per unit square area. With components packed so close together, designs are usually on the extremes and manufacturers must follow tight PCB fabrication and tolerances. Another feature of these designs is the use of components with very high pin count, leading to very fine pin pitch between the pins. This is the origin of the name small pitch PCB assembly, another name being high density PCB assembly.

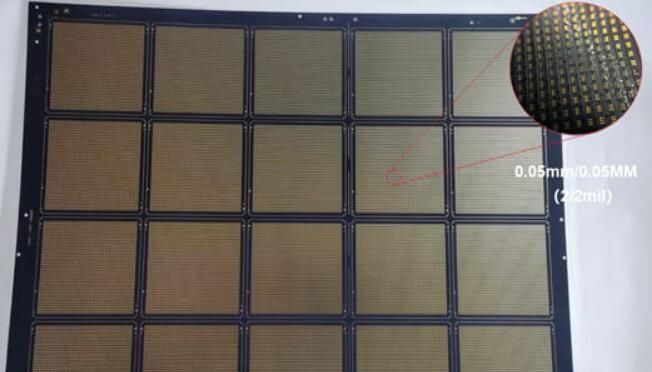

So what is the exact center-to-center distance between the pads and solder balls on the PCB? Some say the distance is within 0.7mm, some say within 25mil (0.625mm), and some say within 0.5mm. At GWT’s assembly fab,the fine-pitch parts it can assemble on PCBs have a pitch within 0.35mm, and the smallest passive footprint it can handle is 01005 (0.4mm×0.2mm). The finest pitch from GWT is 0.05mm.

In the electronics assembly world, the smallest fine-pitch component has a 01005 footprint, and the smallest CSP (Chip Scale Package) devices have only 0.05mm pitch. We call surface mount assembly to this level the ultra-fine pitch assembly. And HDI PCB and BGA PCB may require ultra-fine pitch assembly.

Components for Fine Pitch PCB Assembly

Electronic components for fine pitch PCB assembly can be SMDs, ICs, BGAs, QFPs, and so on, as long as the center-to-center distance between the adjacent pads or solder balls is within 0.5mm. Surface mount devices for fine-pitch assembly are usually 0201, 0402, and sometimes 0603. For fine-pitch components that have solder balls, such as fine-pitch BGAs (FBGAs) and ICs, the distance between the adjacent solder balls is within 0.5mm. For example, the distance between the adjacent pins of the fine-pitch IC as below is 0.3mm.

SMT Stencils for Fine-Pitch pcb Assembly

SMT stencils for fine-pitch pcb assembly are laser-cutting stainless stencils with apertures for the fine-pitch PCB pads. As the fine-pitch SMDs are so small, the pads on the PCB are also small, so solder paste printing through the small holes on the PCB pads is a challenge.

Due to stress concentration, solder paste may be insufficient on the fine-pitch ICs and QFPs. For 0402 and 0201 SMDs, solder paste can be distracted and insufficient as well. Fine-pitch assembly fabs have to specially design the SMT stencils. The apertures cannot be the exact shape and size of the PCB pads.

GWT designs the apertures of the fine-pitch ICs and QFPs to have round ends, and the apertures of the 0402 and 0201 SMDs to be square and a little larger than the pads. This effectively solves the poor soldering problem in fine-pitch assembly.

Pick-and-Place Machines Having Fine-Pitch Assembly Capability

If you are looking for a fine-pitch PCB assembly fab, you should know the SMT assembly capabilities of its pick-and-place machines -- high-speed assembly machine and functional assembly machine. For fine-pitch PCB assembly, the high-speed assembly machine should have the capability to pick and place 0201 SMDs, and the functional assembly machine should be able to pick and place FBGAs, QFPs, etc.

Four-Terminal Sensing to Test Fine-Pitch PCB Assemblies

Fine-pitch PCB assemblies are used for high-density applications with high requirements for circuit performance and precision, and they are often used in military, space, automotive, and medical applications.

At GWT, the four-terminal sensing to fine-pitch PCBA boards have a testing accuracy of ±0.1mΩ and inspects 2,000 to 32,000 test points per time. All PCB assembly houses would appreciate it if their clients provide test points for the signals associated with the fine-pitch components.

Benefits of Fine-Pitch PCB Assembly

Fine pitch PCB assembly saves the PCB space dramatically, and this allows the PCB to carry more components. Products will have more functions and higher performances.

Fine-pitch components such as FBGAs package more circuits than the normal TSOP (thin small outline & package) in the same size.

Fine-pitch PCB assemblies also have better thermal dissipation, because solder balls of the fine-pitch components have more contact areas with the PCB than the normal component pins do.

0users like this.